Products

Super Purchasing for Drilling Mud Decanter Centrifuge Selling

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for Super Purchasing for Drilling Mud Decanter Centrifuge Selling, Honesty is our principle, experienced operation is our function, assistance is our intention, and customers’ gratification is our upcoming!

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for China Decanter Centrifuge for Sludge Dewatering and Centrifuge for Sludge Dewatering, As a well educated, innovative and energetic staff,we are responsible for all elements of the research, design, manufacturing, sales and distribution. With studying and developing new techniques,we have been not only following but also leading the fashion industry. We listen attentively to the feedback from our customers and supply instant communication. You will instantly feel our expertise and attentive service.

Features

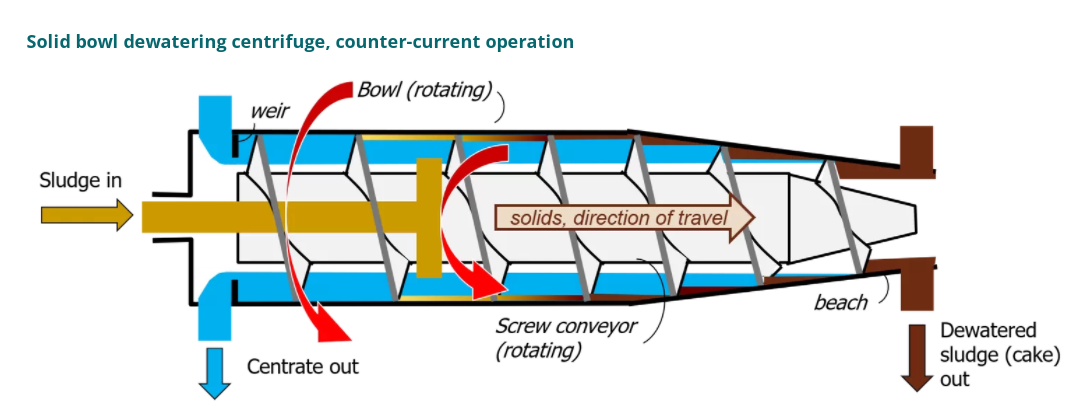

Dewatering Centrifugation is used for both thickening and dewatering of sewage sludge, where dewatered sludge has a higher dry solids (DS) concentration. The centrifuge technologies used for each is almost identical. The key operational differences between the two functions are:

-

the rotation speed employed

-

the throughput, and

-

the nature of the concentrated solids product generated.

Dewatering demands more energy than thickening since more water must be removed to achieve the higher solids concentrations. The dewatered product, whose dry solids (DS) content may be as high as 50%, takes the form of a cake: a deformable semi-solid which forms lumps rather than a free-flowing fluid. It can therefore only be conveyed using a conveyor belt, whereas a thickened product retains the fluid properties of the feed and can be pumped.

As with thickening, the most common type of centrifuge used for dewatering applications is the solid bowl centrifuge, usually referred to as a decanter or a decanting centrifuge. Its dewatering performance and solids recovery depends on the feed sludge quality and dosing conditions

Technical Parameters

|

Model |

TRGLW355N-1V |

TRGLW450N-2V |

TRGLW450N-3V |

TRGLW550N-1V |

|

Bowl Diameter |

355mm (14inch) |

450mm (17.7inch) |

450mm (17.7inch) |

550mm (22inch) |

|

Bowl Length |

1250mm(49.2inch) |

1250mm(49.2inch) |

1600(64inch) |

1800mm(49.2inch) |

|

Max Capacity |

40m3/h |

60m3/h |

70m3/h |

90m3/h |

|

Max Speed |

3800r/min |

3200r/min |

3200r/min |

3000r/min |

|

Rotary Speed |

0~3200r/min |

0~3000r/min |

0~2800r/min |

0~2600r/min |

|

G-Force |

3018 |

2578 |

2578 |

2711 |

|

Separation |

2~5μm |

2~5μm |

2~5μm |

2~5μm |

|

Main Drive |

30kW-4p |

30kW-4p |

45kW-4p |

55kW-4p |

|

Back Drive |

7.5kW-4p |

7.5kW-4p |

15kW-4p |

22kW-4p |

|

Weight |

2950kg |

3200kg |

4500kg |

5800kg |

|

Dimension |

2850X1860X1250 |

2600X1860X1250 |

2950X1860X1250 |

3250X1960X1350 |

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for Super Purchasing for Drilling Mud Decanter Centrifuge Selling, Honesty is our principle, experienced operation is our function, assistance is our intention, and customers’ gratification is our upcoming!

Super Purchasing for China Decanter Centrifuge for Sludge Dewatering and Centrifuge for Sludge Dewatering, As a well educated, innovative and energetic staff,we are responsible for all elements of the research, design, manufacturing, sales and distribution. With studying and developing new techniques,we have been not only following but also leading the fashion industry. We listen attentively to the feedback from our customers and supply instant communication. You will instantly feel our expertise and attentive service.