Products

Renewable Design for Industrial Centrifuge Price Olive Oil 3 Phase Decanter Centrifuge Food

We have by far the most highly developed manufacturing equipment, experienced and qualified engineers and workers, regarded high quality handle systems along with a friendly qualified revenue team pre/after-sales support for Renewable Design for Industrial Centrifuge Price Olive Oil 3 Phase Decanter Centrifuge Food, In purchase to expand our international market, we mainly provide our oversea prospects Top quality performance items and assistance.

We have by far the most highly developed manufacturing equipment, experienced and qualified engineers and workers, regarded high quality handle systems along with a friendly qualified revenue team pre/after-sales support for China Decanter Centrifuge and Decanter Separator, Business philosophy: Take the customer as the Center, take the quality as the life, integrity, responsibility, focus, innovation.We are going to supply expert, quality in return for the trust of customers, with most major global suppliers?ê?all of our employees will work together and move forward together.

Features

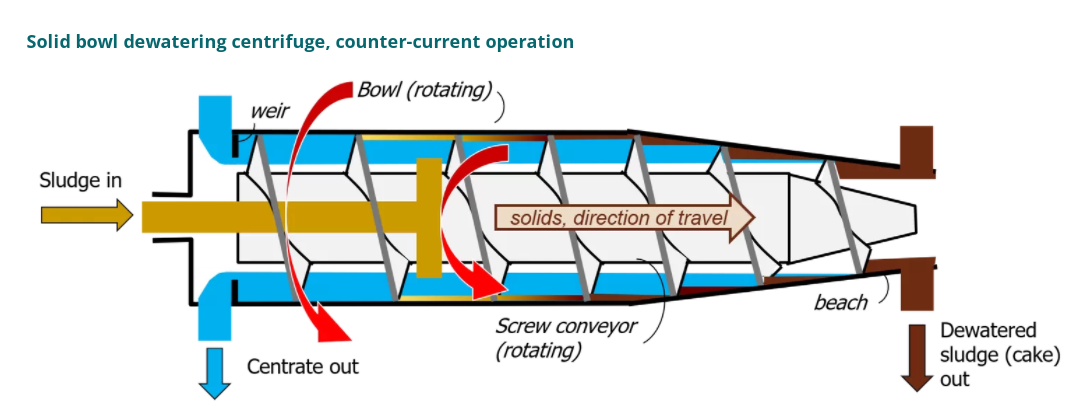

Dewatering Centrifugation is used for both thickening and dewatering of sewage sludge, where dewatered sludge has a higher dry solids (DS) concentration. The centrifuge technologies used for each is almost identical. The key operational differences between the two functions are:

-

the rotation speed employed

-

the throughput, and

-

the nature of the concentrated solids product generated.

Dewatering demands more energy than thickening since more water must be removed to achieve the higher solids concentrations. The dewatered product, whose dry solids (DS) content may be as high as 50%, takes the form of a cake: a deformable semi-solid which forms lumps rather than a free-flowing fluid. It can therefore only be conveyed using a conveyor belt, whereas a thickened product retains the fluid properties of the feed and can be pumped.

As with thickening, the most common type of centrifuge used for dewatering applications is the solid bowl centrifuge, usually referred to as a decanter or a decanting centrifuge. Its dewatering performance and solids recovery depends on the feed sludge quality and dosing conditions

Technical Parameters

|

Model |

TRGLW355N-1V |

TRGLW450N-2V |

TRGLW450N-3V |

TRGLW550N-1V |

|

Bowl Diameter |

355mm (14inch) |

450mm (17.7inch) |

450mm (17.7inch) |

550mm (22inch) |

|

Bowl Length |

1250mm(49.2inch) |

1250mm(49.2inch) |

1600(64inch) |

1800mm(49.2inch) |

|

Max Capacity |

40m3/h |

60m3/h |

70m3/h |

90m3/h |

|

Max Speed |

3800r/min |

3200r/min |

3200r/min |

3000r/min |

|

Rotary Speed |

0~3200r/min |

0~3000r/min |

0~2800r/min |

0~2600r/min |

|

G-Force |

3018 |

2578 |

2578 |

2711 |

|

Separation |

2~5μm |

2~5μm |

2~5μm |

2~5μm |

|

Main Drive |

30kW-4p |

30kW-4p |

45kW-4p |

55kW-4p |

|

Back Drive |

7.5kW-4p |

7.5kW-4p |

15kW-4p |

22kW-4p |

|

Weight |

2950kg |

3200kg |

4500kg |

5800kg |

|

Dimension |

2850X1860X1250 |

2600X1860X1250 |

2950X1860X1250 |

3250X1960X1350 |

We have by far the most highly developed manufacturing equipment, experienced and qualified engineers and workers, regarded high quality handle systems along with a friendly qualified revenue team pre/after-sales support for Renewable Design for Industrial Centrifuge Price Olive Oil 3 Phase Decanter Centrifuge Food, In purchase to expand our international market, we mainly provide our oversea prospects Top quality performance items and assistance.

Renewable Design for China Decanter Centrifuge and Decanter Separator, Business philosophy: Take the customer as the Center, take the quality as the life, integrity, responsibility, focus, innovation.We are going to supply expert, quality in return for the trust of customers, with most major global suppliers?ê?all of our employees will work together and move forward together.