-

Sludge Vacuum Pump

Pneumatic vacuum transfer pump is a kind of pneumatic vacuum transfer pump with high load and strong suction, also known as solid transfer pump or drilling cuttings transfer pump. Capable of pumping solids, powders, liquids, and solid-liquid mixtures. The depth of pumping water is 8 meters, and the lift of discharged water is 80 meters. Its unique structural design enables it to operate in the most difficult environment with low maintenance rate. It can transport materials with more than 80% solid phase and high specific gravity at high speed. It has the following characteristics: the high-efficiency venturi device can generate up to 25 inches Hg (mercury) vacuum under strong air flow to suck materials, and then transport them through positive pressure, with almost no wear parts. It is commonly used for transportation of drilling cuttings, oily sludge, tank cleaning, long-distance transportation of waste suction, and transportation of minerals and wastes. The vacuum pump is a 100% aerodynamic and intrinsically safe pneumatic transportation solution, capable of conveying solids with a maximum inlet diameter of 80%. The unique patented venturi design creates a strong vacuum and high airflow, which can recover up to 25 meters (82 feet) of material and discharge up to 1000 meters (3280 feet). Because there is no internal working principle and no rotating vulnerable parts, it provides a very cost-effective solution for controlling the recovery and transfer of materials that are considered non pumpable.

-

Mud Shear Mixer Pump for Drilling

Mud Shear Mixer Pump is a special purpose equipment in solids control system.

Mud Shear mixer pump is mostly used in manufacturing fluids like oil. Most of the industries prefer to produce oil along with water for which liquids have to be dispersed. Mud Shear mixer pumps are used for creating shear forces that are effective in dispersing the liquids that have different densities and molecular structures. Shear pumps are widely preferred by most people working for industries and factories.

Mud Shear Mixer Pump is a special purpose equipment in solids control system which can meet all customers’ requirements of preparing dilling fluid for oil drilling. Its design has a special impeller structure, which produces a strong shear force when liquid flows. By smashing and dispersing chemical particles, soil and other solid phase in liquid flow, so that the liquid in the solid phase broken and distributed evenly. This ideal solids control equipment designed by TR’s engineers has high performance and gains customer’s high evaluation.

-

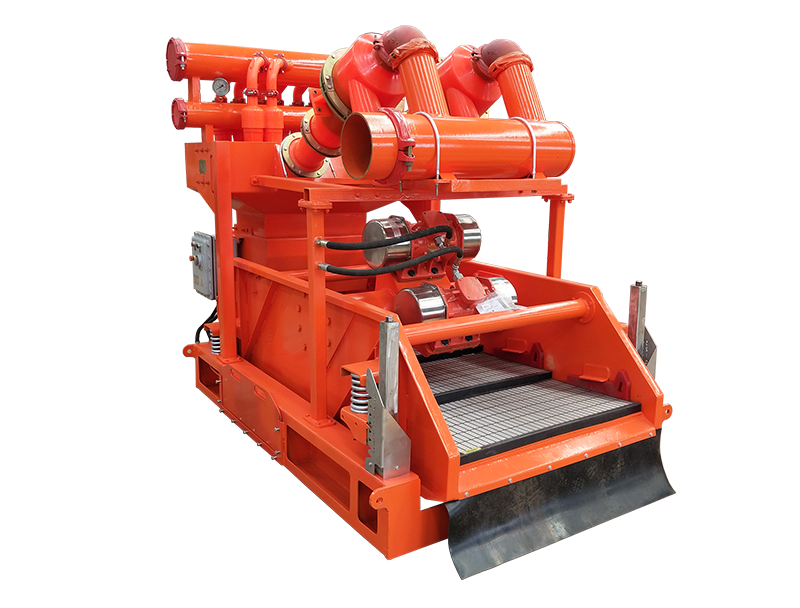

Mud Cleaner in Drilling rig

Mud Cleaner equipment is a combination of desander, desilter hydro cyclone with an underflow shale shaker. TR Solids Control is Mud Cleaner manufacture.

Mud cleaner is a versatile device that is used to separate big solid components and other slurry materials from drilled mud. In this article, we’re going to talk about the Mud Cleaner from TR Solids Control.

Mud Cleaner equipment is a combination of desander, desilter hydro cyclone with an underflow shale shaker. To overcome limitations that are present in many solid removal equipment, ‘new’ equipment was developed with the purpose of removing drilled solids from weighted muds. The Mud Cleaner does remove most of the drilled solids while also retaining the barite as well as the liquid phase present in the mud. The discarded solids are sieved to discard larger solids, and returned solids are smaller even from the screen size of the liquid phase.

Mud Cleaner is the second class and the third class solids control equipment which is the newest type to treat the drilling fluid. At the same time drilling Mud cleaner has the higher cleaning function compared with separated desander and desilter. In addition to the reasonable design process, it equals another shale shaker. Fluids mud cleaner structure is compact, it occupys small space and the function is powerful.

-

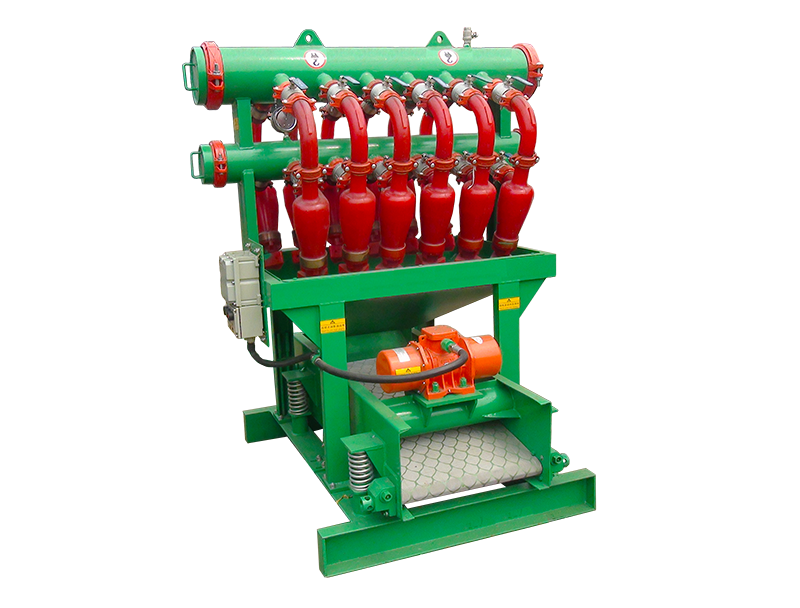

Drilling Mud Desilter for Mud Solids Control

Drilling Mud Desilter is an economic compact desilting equipment. Desilter is used for drilling fluids solids control system.

Drilling Mud Desilter is a very important piece of equipment in the mud cleaning process. The principle of working in hydro cyclones is the same as desanders. Desilter uses smaller hydro cyclones compared to Drilling Desander for the treatment, which enables it to remove even smaller particles from the drill fluid. The smaller cones allow the desilter to remove solids hello over the 15 microns size. Each cone achieves consistently 100 GPM.

Drilling Mud Desilter is typically used after the drill fluid has been processed through the mud desander. It uses smaller hydro cyclones compared to Drilling Desander for the treatment, which enables it to remove even smaller particles from the drill fluid. The smaller cones allow the desilter to remove solids hello over the 15 microns size. Each cone achieves consistently 100 GPM. Drilling Desilter is the process of fine particle size separation. It is a very important piece of equipment in the mud cleaning process. The desilter reduces the average particle size while also removing abrasive grit from the unweighted drill fluid. The principle of working in hydro cyclones is the same as desanders. The only difference is that the drilling mud desilter makes a final cut, and the capacity of the individual cone is significantly lower. Multiple such cones are utilized for the process and manifolded into a single unit. Desilter is sized 100% – 125 % of the flow rate into the desilter. A Siphon breaker is also installed with the overflow manifold from the cones.

-

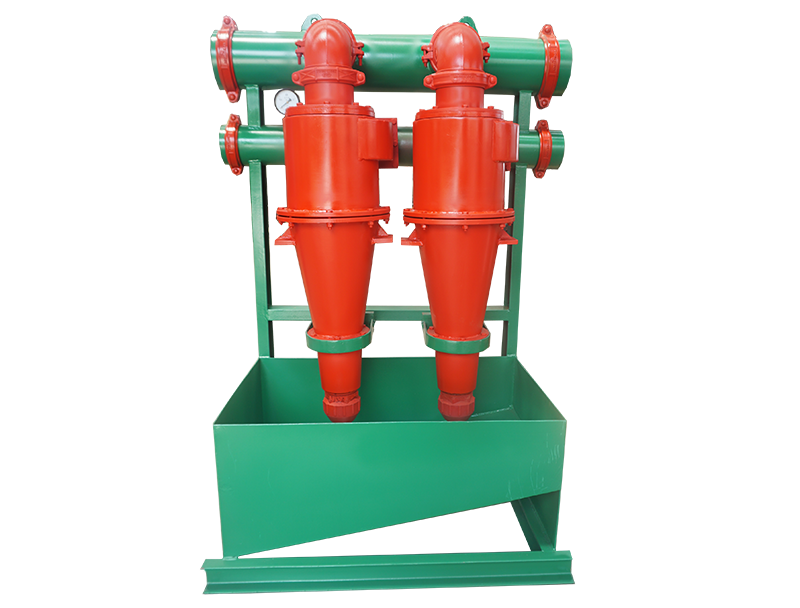

Drilling Mud Desander Consists of Desander Cyclone

TR Solids control produce mud desander and drilling fluids desander.Drilling Mud Desander for Mud Circulating System. Drilling Mud Desander Consists of Desander Cyclone.

Drilling Fluids Desander for Mud Circulating System Mud Desander also called drilling fluids Desander, It is the third piece of equipment in the mud recycling system. Mud Desander is used after the drill fluid has already been treated under the mud shale shaker and mud degasser. Mud Desanders make separations between 40 and 100 microns and offer the flexibility of mounting either one, two, or three 10” desander cyclone over a cone underflow pan.

Mud Desander is a useful mud recycling equipment that removes the solid particles within a specific range, from the mud (or drill fluid). Mud Desanders make separations between 40 and 100 microns and offer the flexibility of mounting either one, two, or three 10” desander cyclone over a cone underflow pan. The underflow can be discarded or directed onto a vibrating screen for further processing. Drilling Fluids Desanders are also available in vertical or inclined manifold stand-alone models, or for inclined mounting on Drilling Shale Shakers.

-

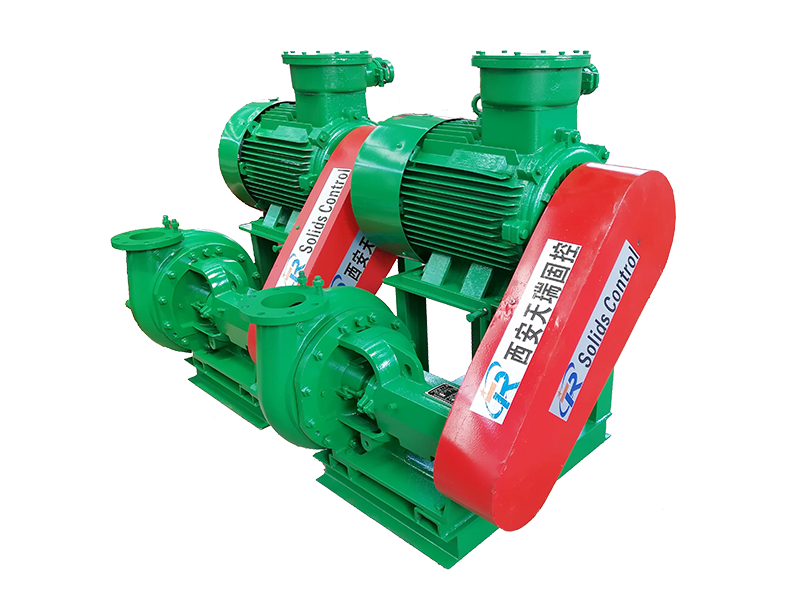

Mud Centrifugal Pump could replace Mission Pump

Drilling Mud Centrifugal pump is often used for desander and desilter mud supply system. Mission Pump mainly supplies to solids control circulating system of oilfield drill rig.

Mud Centrifugal Pumps is designed and engineered to handle abrasive, viscous and corrosive fluids in drilling fluid or industrial slurry applications. Mission Pump performance is matched by exceptional performance, high volume, high temperature capabilities, long service life, ease to maintenance, overall economy and greater savings. Centrifugal Mud Pumps are currently in operation on land-based and offshore drilling rigs around the world. We will offer the best choice for the intended application, taking into consideration fluid conditions.

Mission Pump mainly supplies to solids control circulating system of oilfield drill rig,and be used to provide drilling liquid with a certain discharge capacity and pressure to sand, desilter and mud mixer,to assure these equipments work efficiently.Mud Centrifugal pump adopts advanced design theory for pumping drilling fluid or industrial suspension (slurry).Drilling mud centrifugal pump can pump abrasive, viscosity and corrosive liquid. We will provide customers with the best products to meet the needs of different conditions.

-

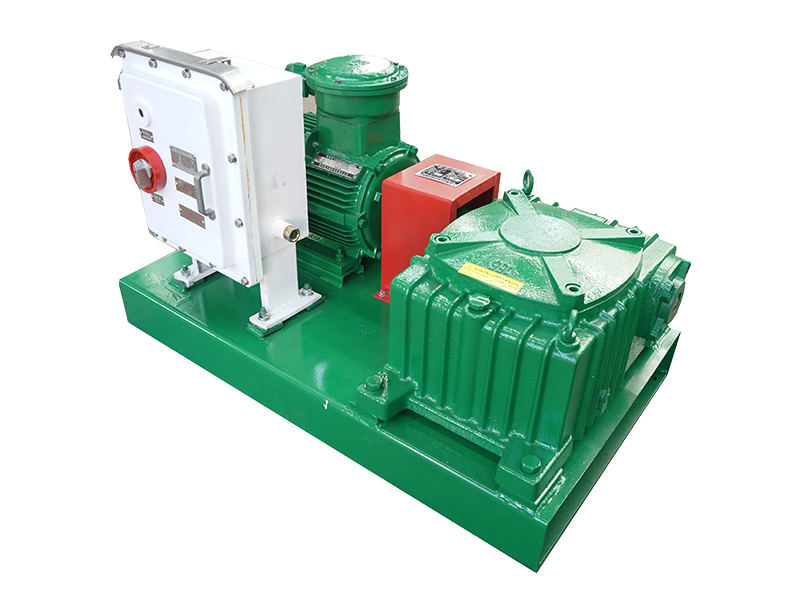

Mud Agitators for Drilling Mud Tank

Mud Agitator and Drilling fluids agitator are used for solids control system. TR Solids Control is an mud agitators manufacturer.

Mud Agitators are designed to mix and suspend the solids using axial flow, promoting low particle size degradation and effective polymer shear. Unlike mud guns, the mud agitator is relatively a low energy device, easy to operate and inexpensive to maintain. Our standard horizontal and vertical mud agitators range in 5 to 30 horsepower with an explosion proof motor and gear reducer. We size mud agitators according to the configuration and maximum mud weight. TR Solids Control is an Drilling fluids agitator manufacturer.

Drilling Mud Agitators are designed to mix and suspend the solids using axial flow, promoting low particle size degradation and effective polymer shear. Unlike mud guns, the mud agitator is relatively a low energy device, easy to operate and inexpensive to maintain. Our standard horizontal and vertical mud agitators range in 5 to 30 horsepower with an explosion proof motor and gear reducer. We size mud agitators according to the configuration and maximum mud weight.