-

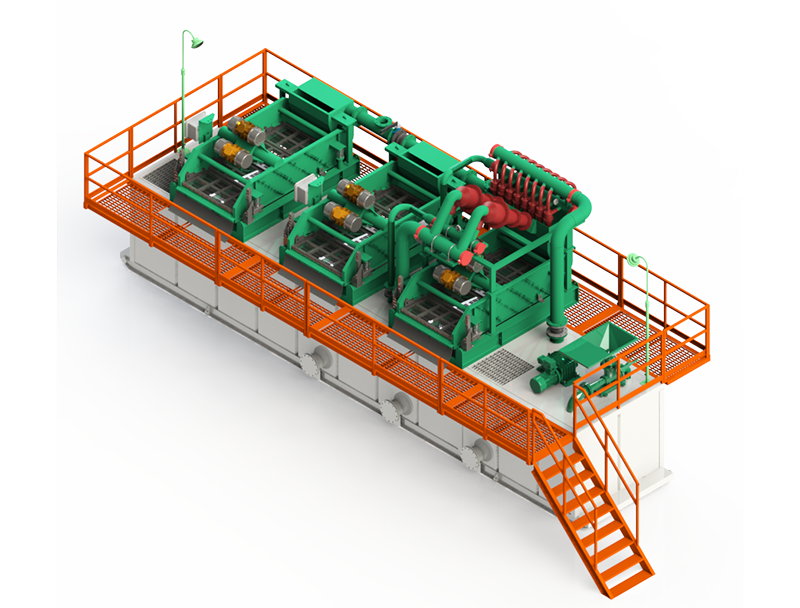

Mud Recovery System | Mud Recycling System

Mud Recovery System is an important part of directional drilling and pipe jacking construction. TR is Mud Recycling System manufacturer.

Mud Recovery System is an important part of directional drilling and pipe jacking construction. Mud Recycling System has the function of recycling, purifying and preparing the mud.

mud recycling system is suitable for construction projects with high mud capacity. Mud recovery system purification process is divided into three stages :The first stge of mud shale shaker, the second and the third stage of desander and desilter. Both desander and desilter are equipped with underflow shale shaker to further treat solids discharged from the upper equipment. Necessary mud material is added to the purification slurry through mud preparation device, after stirring uniformly to prepare slurry with qualified recovery performance. This reduces the construction cost greatly and protects the environment effectively.

-

Dewatering centrifuge

TR Solids Control is an Dewatering centrifuge Supplier. The sludge dewatering centrifuge produced by TR Solids Control has been widely praised by customers.

A sludge dewatering centrifuge uses a fast rotation of a “cylindrical bowl” to separate wastewater liquid from solids. The wastewater centrifuge dewatering process removes more water than other methods and leaves solid material that is known as cake. Dewatering means less tank space is needed to store waste products.

-

Best Popular Mud Shale Shaker for oil drilling

Drilling Shale Shaker is the third generation of linear motion shaker.Drilling Shale Shaker is using the horizontal excitation of vibration motor as vibration source, material on the sieve was up forward for linear motion,referred to as Linear Shaker, also known as linear shaker; Drilling Shale Shaker is the most widely used mud shale Shaker. All Mud Shale Shaker is TR Solids Control designed by ourselves, including Balanced Elliptical motion Shaker and Mongoose shale shaker.All shaker screens can be fit on shakers by wedge blocks or hooks.We can according to customer’s demand, linear motion, or balanced elliptical motion and double-track movement.

-

Drilling waste management for Drilling Cutting

Drilling waste management is used for taking drilling fluids from the drilling cuttings and clean the fluids for resuse.

Drilling waste management system are drying shaker, vertical cutting dryer, decanter centrifuge, screw conveyor, screw pump and mud tanks. The drilling waste management can effectively control the moisture content (6%-15%) and oil content (2%-8%) in drilling cuttings and stabilizes the liquid phase performance.

Drilling waste management system, also called as drill cutting treatment system or drilling cutting management system. According to different applications, it can be classified as water-based drilling waste management system and oil-based drilling waste management system. The main system equipments are drying shaker, vertical cutting dryer, decanter centrifuge, screw conveyor, screw pump and mud tanks. The drilling waste management system can effectively control the moisture content (6%-15%) and oil content (2%-8%) in drilling cuttings and stabilizes the liquid phase performance.

TR drilling waste management is used for taking drilling fluids from the drilling cuttings and clean the fluids for resuse. It is to maximize the recycling of drilling fluids, and minimize the drilling waste in order to save cost for operators.

-

Venturi Hopper is used for Drilling Mud Mixing Hopper

Jet Mud Mixer is composed of mud mixing hopper and centrifugal pump. Venturi hopper is also called mud hopper. TR solid control is an exporter of Drilling Mud Mixing Hopper.

Drilling Mud Mixing Hopper is specialized equipment used in the solid control process. Its purpose is to configure and aggravate the drilling fluid. This results in changes in the density, viscosity, and pH levels of the drilling fluid. The drilling fluid and other drilling additives are appropriately blended and homogenized. Mud hopper is crucial that the drilling fluid materials and the addition agents are first entered into the mud tank as otherwise, they could precipitate or conglobate. The Jet Mud Mixer prevents that from happening.

Drilling Mud Mixing Hopper is safe and stable solid control equipment that can be moved conveniently without any issue. It contains a centrifugal pump, venturi hopper, base, and pipelines. Centrifugal pump is fixed on the base and operated via an electric motor. The fluid is entered via the impeller. Mud Hopper mixes the additives into the system and is connected with the pump via the pipelines. All of these are fixed with the base for smooth functioning. Jet Mud Mixer eases life and the electric motor is of the best quality.

-

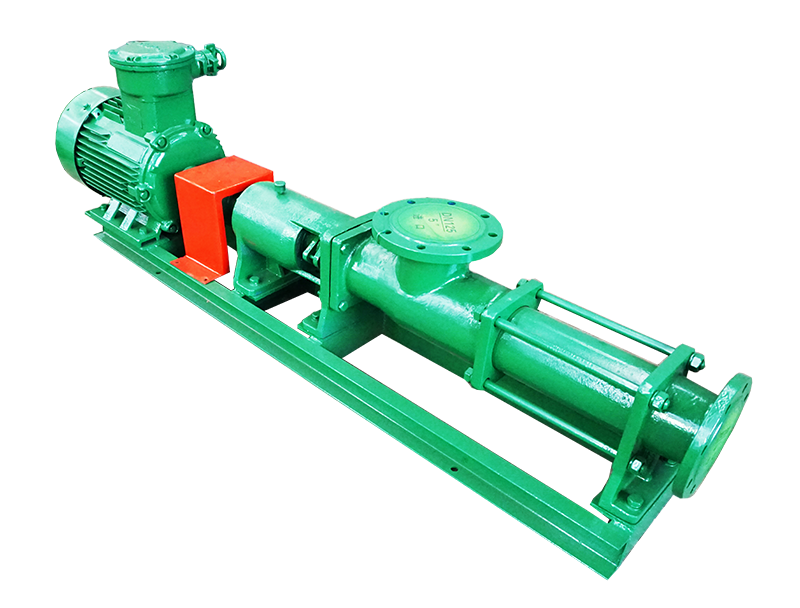

Screw Pump for Decanting Centrifuges

Screw Pump is usually used for supplying mud/slurry to centrifuge in solids control industry.

The screw pump is used for industrial purposes. It is beneficial in allowing the movement of fluids and solids along the screw axis. A screw pump is also called a water Screw. It uses either one or several skills to move the fluid along the screw axis in the manufacturing and industrial methods.

Screw Pump is usually used for supplying mud/slurry to centrifuge in solids control industry. It has features of good feeding capacity and stable working pressure. It is the ideal choice to convey the flocculated waste drilling fluids with high viscosity and hard suspended solids, because the volume change of sealed cavity formed by screw and stator sucks and discharges the fluid without drastic fluid mixing activity.

TRG series screw pump has the features of less accessories, compact structure, easy maintenance and vulnerable part replacement. In addition to the drilling fluids centrifuge, the rated pressure of our pump outlet can be increased with the increase of the pump series, and the pressure will increase 0.6MPa, so its using range is very wide.

-

Drilling Mud Decanter Centrifuge for oil drilling

TR solids control is the production Drilling Mud Decanter Centrifuge and waster decanter centrifuge manufacturer.

Drilling Mud decanter Centrifuge is widely used in oil and gas drilling, Waste Decanter Centrifuge used in vertical cuttings dryer, remove all the solids in the drilling fluids.

Drilling Mud decanter centrifuge adopts centrifugal force to separate solid particles out of drilling fluid. Different solid or particle have different density and flow speed, drilling mud decanter centrifuges also can separate particles as different size and density. Mud Centrifuges is widely used in oil and gas drilling, chemical, foodstuff, pharmacy, mineral beneficiation, water treatment, etc. industries.Waste Decanter Centrifuge used in drilling waste management(DWM).

-

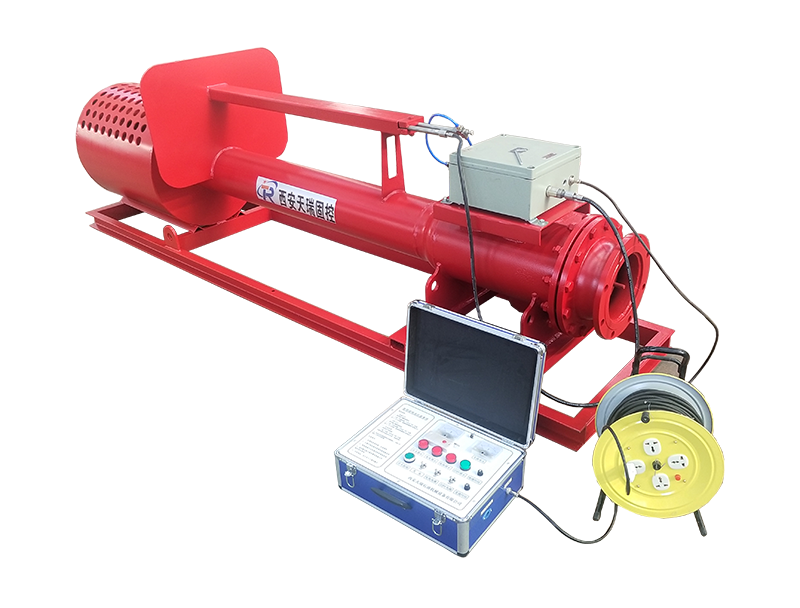

Flare Ignition Device

The Flare Ignition Device is used in conjunction with the Mud Gas Separator. flare ignition device is a handy tool to light the wasted gas in the industry of oil and gas. This tool is being used to burn poisonous or harmful gas by igniter which will ensure the safety of the environment and eliminate the threat.

The Flare Ignition Device is used in conjunction with the Mud Gas Separator. flare ignition device is a handy tool to light the wasted gas in the industry of oil and gas. This tool is being used to burn poisonous or harmful gas by igniter which will ensure the safety of the environment and eliminate the threat.

Flare ignition device is a special oil drilling equipment to handle the invaded gas, it is also an effective equipment to handle the tail gas and invaded natural gas in oil field, refinery and natural gas collecting and distributing station. It can ignite the harmful invaded gas to eliminate the hazards to the environment, also it is a security environmental protection equipment. This equipment can match with mud gas separator, and is usually used in oil & gas drillingand CBM drilling project. Flare ignition device for gas ignition control in oilfield is equipped to burn on the oil and natural gas drilling field in case of flammable and poisonous gas overflow while drilling and eliminate the harm to the environment and ensure safety. It consists of a gas guiding pipe, an ignition device, a torch and an explosion-proof hose, integrating high pressure electronic ignition and gas combustion.

-

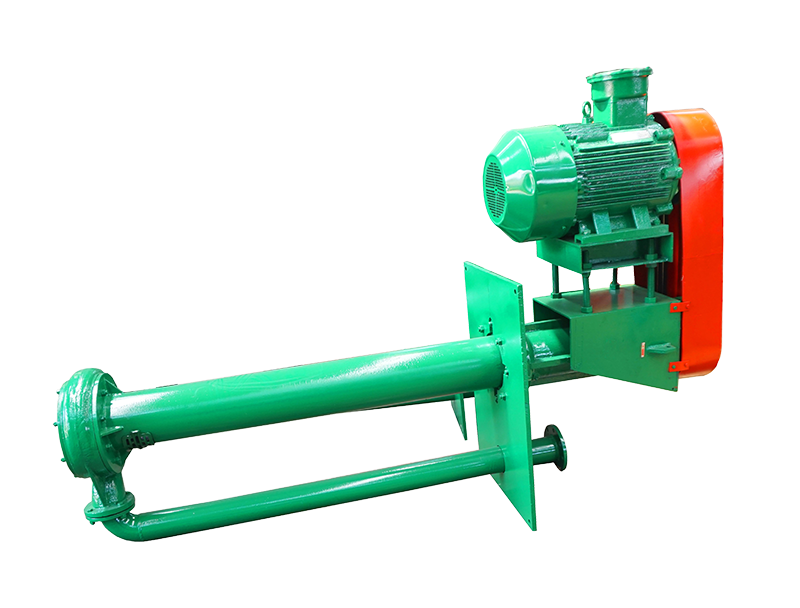

Submersible Slurry Pump

Submersible Slurry Water Pump is a vital part of the mud cleaning process. TR Solids Control is Submersible Slurry Pump manufacture.

These are heavy-duty pumps that are very beneficial for pumping all types of heavy liquids that contain solid particles. They can be used for multiple purposes like industrial, construction, sewage, etc. people who are linked to these professions know the importance of submersible slurry pumps.

A Submersible Slurry Water Pump is a vital part of the mud cleaning process. They are primarily used as the oil drilling solids control system but can also be utilized for pumping concentrated liquids and mud. The mud is recycled through the Submersible Slurry Pump, which treats the fluid. They are made to be highly efficient and serve for an extended period. The Submersible Slurry Pump transport solid as well as liquid particles through the pipe, which are then recycled and transported to the other essential pieces of equipment that are part of the mud treatment process.

Submersible slurry pump is one kind of Centrifugal Pump. It mainly supply mud for shale shaker and decanter centrifuge from the mud pit. It transfers liquid and solid mixture. Raw material of our submersible slurry pump is rather anti-abrasive. It can transfer different hard materials. Including sand, cement, particles, shale, and so on.

-

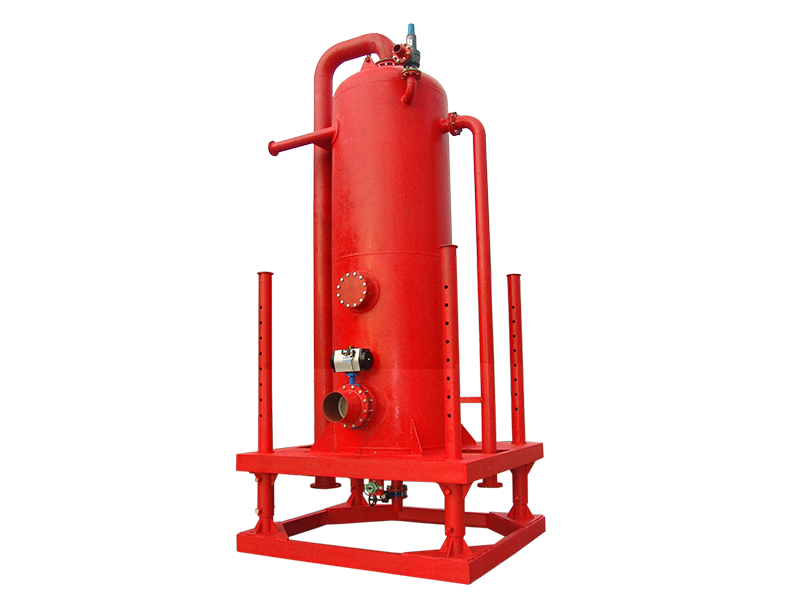

Mud gas separator for Drilling Fluids System

Mud Gas Separator also known as poor boy degasser is a special tool designed particularly for degassing gas-invaded mud effectively in the first grade.

Mud Gas Separator is uniquely designed for effective separation of the mud and gas circulated due to the venting of the gas. mud gas separator also known as poor boy degasser is a special tool designed particularly for degassing gas-invaded mud effectively in the first grade.

Mud Gas Separator is uniquely designed for effective separation of the mud and gas circulated due to the venting of the gas and also for the returning of the mud to the pits. The remaining amount of the gas, which is significantly smaller than the initial quantity, is then headed off to be handled by the vacuum degasser. Mud Gas Separator is a vital component of the solid control system. The Mud Gas Separator controls the gas cutting when the situation demands; it is primarily utilized during drilling when there is a significant presence of drilled gas in the mud returns. The Mud Gas Separator removes the bubbles with a diameter equal to or larger than φ3mm.Most of these bubbles are the expanded gas filled in the drilling fluid in the annular of wellbore, which might cause well kick if not to remove it timely.

-

Vertical Cutting Dryer for Drilling Cuttings Recovery

Vertical Cutting Dryer uses centrifugal force to dry drilled solids.

Vertical Cuttings Dryer continues to be the industry choice as the most reliable and efficient solution when dealing with waste cuttings. The TR Vertical Cutting Dryer uses centrifugal force to dry drilled solids in oil or synthetic base fluids. Vertical cuttings dryer can recover up to 95% of drilling fluids. vertical dryer cuttings that can range between 6% and 1% oil by weight.

Vertical Cutting Dryer is a single level continuous working horizontal scraper discharging centrifuge. TR series It can effectively recover the oil components in the drilling chips, and can effectively meet the requirements of curing transportation and meet the requirements of environmental protection standards. A stainless steel screen bowl traps “wet” solids and accelerates them up 900RPM with G force to 420G. Vertical Cutting Dryer is very good. Liquid is forced through the screen bowl openings, while “dry” solids are extracted by the angled flights attached to the cone, which rotate slightly slower than the bowl. Tungsten carbide protects the flights from abrasive solids and ensures long operational life. This aids in maintaining a constant gap between the scroll and screen bowl, which is crucial for proper operation.

Vertical cuttings dryer can recover up to 95% of drilling fluids. vertical dryer cuttings that can range between 6% and 1% oil by weight.

-

Mud Vacuum Degasser for Drilling Fluids System

Mud Vacuum Degasser and Drilling Vacuum Degasser are special purpose product for gas treatment in drilling fluids.

Mud Vacuum Degasser is the most common form of degassing systems used in the oil & gas industry. Drillng fluid is pulled into the tank by vacuum action. The fluid rises inside the tank and is distributed over a series of plates which releases the gas bubbles from the drilling fluid.

Mud Vacuum Degasser is a special purpose product for gas treatment in drilling fluids. This unit is positioned downstream from shale shaker, mud cleaner and mud gas separator, while hydrocyclones and centrifuges follow in the arrangement. It is used to remove small entrained gas bubbles left in the mud by mud gas separator.

Mud Vacuum Degasser is also called mud/Gas separator. Mud/gas separators (Degasser) is the first units of solids control equipment arranged to treat drilling mud. As such, they process all of the drilling mud from the flow line before the mud reaches the primary shale shakers.