In the realm of drilling operations, efficiency and productivity are of paramount importance. To achieve optimal results, drilling companies rely on various equipment and systems, one of which is the mud tank agitator. This essential component plays a crucial role in maintaining the integrity and functionality of the drilling system, ensuring a smooth and productive drilling process.

A mud tank agitator is a mechanized device designed to maintain the homogeneity of the drilling fluid, also known as mud, which is vital for successful drilling operations. This equipment is installed in a mud tank, where it vigorously stirs and blends the mud, preventing the sedimentation of solid particles and maintaining a consistent fluid density. By doing so, the mud tank agitator ensures that the drilling fluid retains its desired properties and can effectively carry out its functions.

The importance of a mud tank agitator in a drilling system cannot be overstated. Without proper agitation, the mud will settle, leading to a loss of its desired characteristics. Sedimentation can cause blockages, decreased drilling efficiency, and even equipment failure, ultimately resulting in costly downtime on the drilling site.

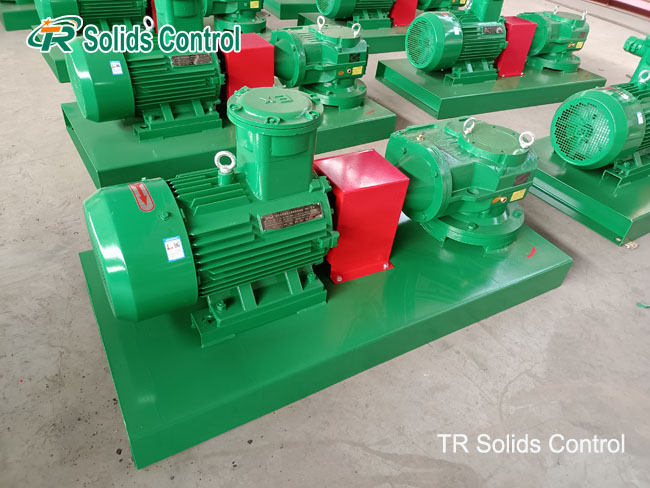

A well-designed mud tank agitator combines power and efficiency to maximize its performance. It typically consists of a motor, gearbox, shaft, and impellers. The motor provides the necessary power to drive the agitator, while the gearbox facilitates the transmission of this power to the shaft. The impellers, attached to the shaft, create the desired turbulence within the mud, keeping the solids in suspension and preventing them from settling at the bottom of the tank.

When selecting a mud tank agitator for a drilling system, several factors need to be considered. The size of the mud tank, the viscosity of the drilling fluid, and the desired blending intensity are some of the key variables that determine the appropriate agitator specifications. Additionally, the agitator should be durable and resistant to harsh drilling conditions, ensuring a long operational life and minimizing maintenance requirements.

An efficient mud tank agitator offers numerous benefits to drilling operations. Firstly, it improves the overall performance of drilling rigs by maintaining the drilling fluid’s viscosity and density. This, in turn, enables better hole cleaning, lubrication, and cooling, leading to enhanced drilling efficiency and reduced wear and tear on drilling equipment.

Furthermore, the continuous agitation provided by a mud tank agitator effectively prevents the settling of solids. This is particularly important in wells with long idle periods, where sedimentation is more likely to occur. By keeping the solids suspended, the agitator ensures that the drilling fluid is ready for immediate use, minimizing downtime and optimizing drilling performance.

In conclusion, a mud tank agitator plays a vital role in maintaining the integrity and functionality of a drilling system. Its ability to blend and stir the drilling fluid ensures a consistent and well-functioning mud, improving drilling efficiency and preventing equipment failure. When selecting a mud tank agitator, it is crucial to consider factors such as tank size, fluid viscosity, and blending intensity to ensure optimal performance. By investing in a reliable and efficient mud tank agitator, drilling companies can enhance their operations, improve productivity, and ultimately achieve greater success on the drilling site.