A mud solids control system plays a vital role in the drilling industry as it is responsible for separating drilling fluid from cuttings and other hazardous materials. Without a proper mud solids control system, drilling operations can become less efficient, more dangerous and more costly as large amounts of waste material can accumulate and contaminate the environment, leading to safety concerns and regulatory issues.

To prevent such problems, it is critical to have a reliable mud solids control system installed at the drilling site so that it can remove solids and other contaminants from the drilling fluid and recover and reuse the drilling fluid to maximize Reduce waste and reduce costs. A high-quality mud solids control system can also improve overall drilling efficiency because it helps maintain mud specific gravity, viscosity, and other properties needed for efficient drilling, and prevents excessive solids or gas in the well body fluids resulting in equipment damage and downtime.

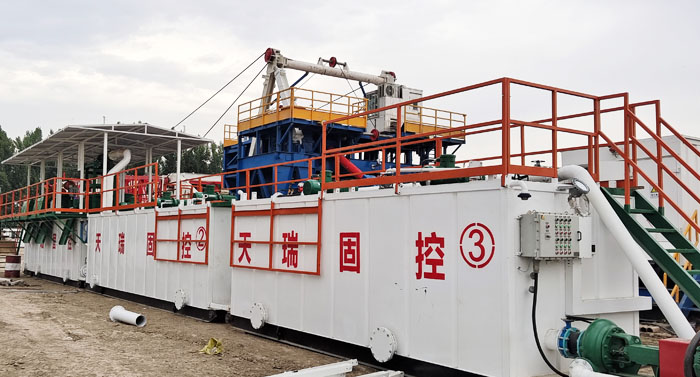

At TR Solids Control, we provide a full range of mud solids control system solutions to meet the drilling needs of global customers. Our mud solids control systems are designed to handle a wide variety of drilling conditions, from soft soils to hard rock formations, and can be customized to meet the specific requirements of each drilling project.

When the mud solids control system is shipped to the drilling site, it usually consists of several components such as vibrating screens, vacuum degassers, desanders, desilters and centrifuges, as well as mud tanks, piping and other required auxiliary Equipment transports and recovers fluids. These components need to be installed and connected carefully to maximize efficiency and keep them safe.

Once a mud solids control system is installed, it can begin to perform its function by separating and removing solids and other materials that are not needed for drilling. Solids control equipment, such as shakers and hydrocyclones, can capture cuttings and dispose of them in a safe and environmentally friendly manner, while mud tanks can store and recirculate drilling fluids and add or remove chemicals and additives as needed to keep the mud characteristic.

The benefits of installing a mud solids control system at a drilling site are numerous. On the one hand, the system helps reduce the amount of waste generated during drilling, saving costs and reducing the environmental impact. It also improves drilling efficiency by maintaining mud properties and minimizing formation damage, and reduces drilling-related risks such as blowouts, pump failures and safety hazards.

Additionally, a mud solids control system can improve the overall quality and safety of drilling operations by ensuring that drilling fluids are clean, consistent and free of harmful contaminants that could cause equipment damage or health risks. It can also help meet regulatory compliance requirements and preserve the drilling company’s reputation.

In conclusion, when a mud solids control system is shipped to a drilling site and installed properly, it can be a valuable asset in maximizing drilling efficiency, reducing drilling risk and protecting the environment. At GN Solids Control, we strive to provide customers with the best mud solids control system solutions that are reliable, efficient and cost-effective. We believe that by partnering with our customers, we can achieve successful and sustainable drilling operations that meet the highest standards of safety, performance and quality.