-

Hot-selling Lab Horizontal Decanter Centrifuge for Drilling Mud

TR solids control is the production Drilling Mud Decanter Centrifuge and waster decanter centrifuge manufacturer.

Drilling Mud decanter Centrifuge is widely used in oil and gas drilling, Waste Decanter Centrifuge used in vertical cuttings dryer, remove all the solids in the drilling fluids.

Drilling Mud decanter centrifuge adopts centrifugal force to separate solid particles out of drilling fluid. Different solid or particle have different density and flow speed, drilling mud decanter centrifuges also can separate particles as different size and density. Mud Centrifuges is widely used in oil and gas drilling, chemical, foodstuff, pharmacy, mineral beneficiation, water treatment, etc. industries.Waste Decanter Centrifuge used in drilling waste management(DWM).

-

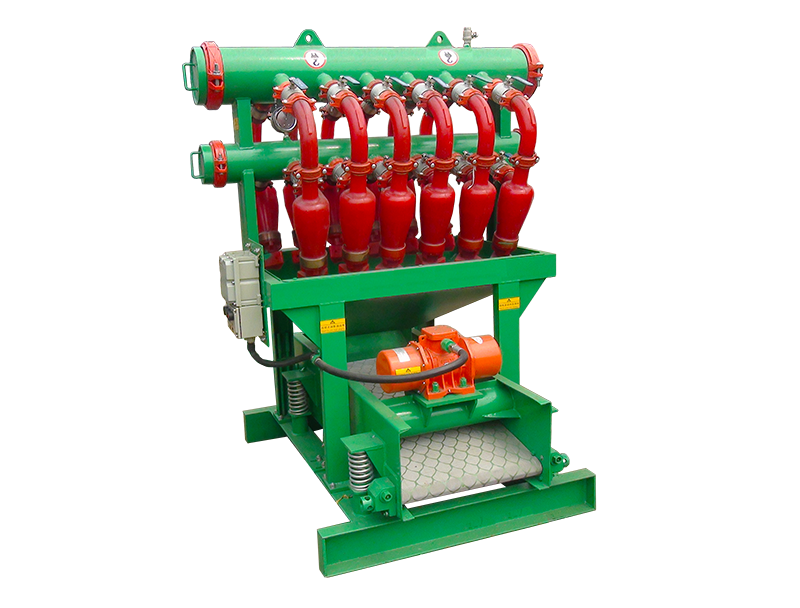

OEM/ODM Manufacturer Drilling Fluid Desilter for Oilfield Drilling Mud System

Drilling Mud Desilter is an economic compact desilting equipment. Desilter is used for drilling fluids solids control system.

Drilling Mud Desilter is a very important piece of equipment in the mud cleaning process. The principle of working in hydro cyclones is the same as desanders. Desilter uses smaller hydro cyclones compared to Drilling Desander for the treatment, which enables it to remove even smaller particles from the drill fluid. The smaller cones allow the desilter to remove solids hello over the 15 microns size. Each cone achieves consistently 100 GPM.

Drilling Mud Desilter is typically used after the drill fluid has been processed through the mud desander. It uses smaller hydro cyclones compared to Drilling Desander for the treatment, which enables it to remove even smaller particles from the drill fluid. The smaller cones allow the desilter to remove solids hello over the 15 microns size. Each cone achieves consistently 100 GPM. Drilling Desilter is the process of fine particle size separation. It is a very important piece of equipment in the mud cleaning process. The desilter reduces the average particle size while also removing abrasive grit from the unweighted drill fluid. The principle of working in hydro cyclones is the same as desanders. The only difference is that the drilling mud desilter makes a final cut, and the capacity of the individual cone is significantly lower. Multiple such cones are utilized for the process and manifolded into a single unit. Desilter is sized 100% – 125 % of the flow rate into the desilter. A Siphon breaker is also installed with the overflow manifold from the cones.

-

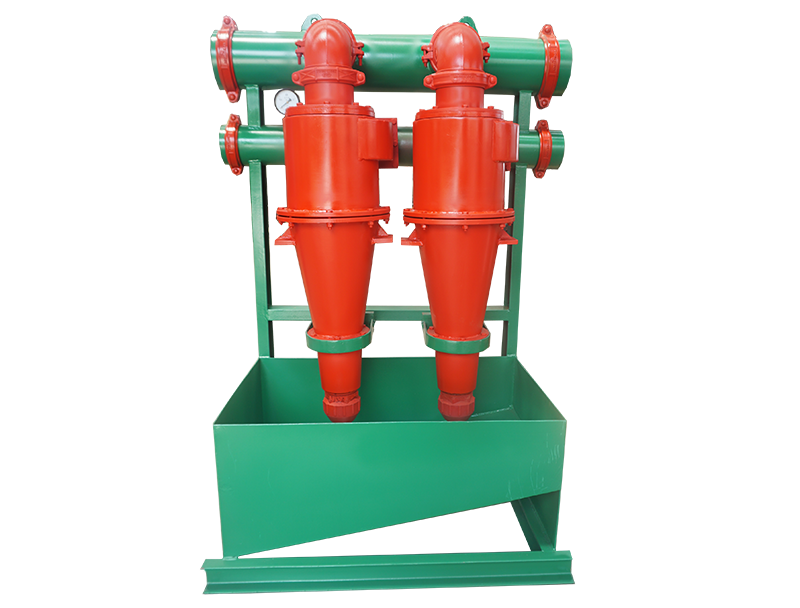

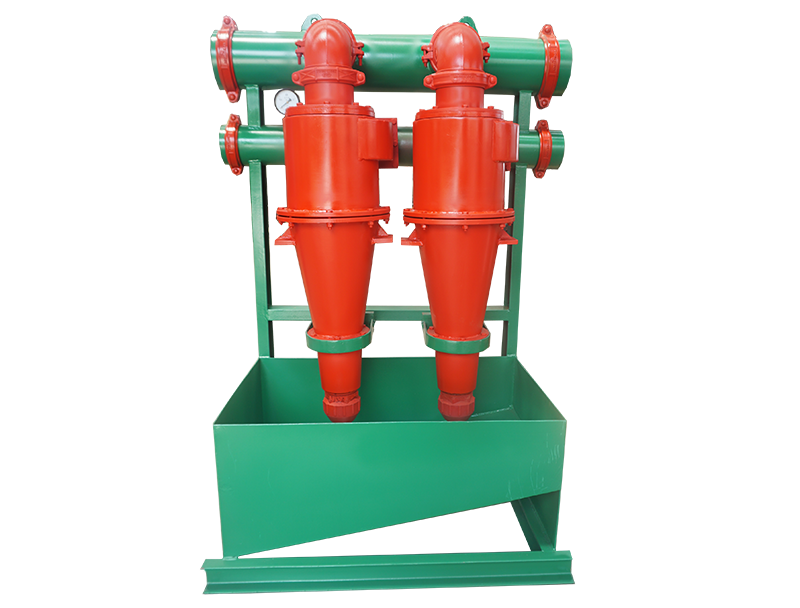

OEM Factory for Mud Desander for Oilfield Mud Cleaning and Solids Control System

TR Solids control produce mud desander and drilling fluids desander.Drilling Mud Desander for Mud Circulating System. Drilling Mud Desander Consists of Desander Cyclone.

Drilling Fluids Desander for Mud Circulating System Mud Desander also called drilling fluids Desander, It is the third piece of equipment in the mud recycling system. Mud Desander is used after the drill fluid has already been treated under the mud shale shaker and mud degasser. Mud Desanders make separations between 40 and 100 microns and offer the flexibility of mounting either one, two, or three 10” desander cyclone over a cone underflow pan.

Mud Desander is a useful mud recycling equipment that removes the solid particles within a specific range, from the mud (or drill fluid). Mud Desanders make separations between 40 and 100 microns and offer the flexibility of mounting either one, two, or three 10” desander cyclone over a cone underflow pan. The underflow can be discarded or directed onto a vibrating screen for further processing. Drilling Fluids Desanders are also available in vertical or inclined manifold stand-alone models, or for inclined mounting on Drilling Shale Shakers.

-

Hot sale Filter Cartridge Dust Removal System Type Dust Collector

Jet Mud Mixer is composed of mud mixing hopper and centrifugal pump. Venturi hopper is also called mud hopper. TR solid control is an exporter of Drilling Mud Mixing Hopper.

Drilling Mud Mixing Hopper is specialized equipment used in the solid control process. Its purpose is to configure and aggravate the drilling fluid. This results in changes in the density, viscosity, and pH levels of the drilling fluid. The drilling fluid and other drilling additives are appropriately blended and homogenized. Mud hopper is crucial that the drilling fluid materials and the addition agents are first entered into the mud tank as otherwise, they could precipitate or conglobate. The Jet Mud Mixer prevents that from happening.

Drilling Mud Mixing Hopper is safe and stable solid control equipment that can be moved conveniently without any issue. It contains a centrifugal pump, venturi hopper, base, and pipelines. Centrifugal pump is fixed on the base and operated via an electric motor. The fluid is entered via the impeller. Mud Hopper mixes the additives into the system and is connected with the pump via the pipelines. All of these are fixed with the base for smooth functioning. Jet Mud Mixer eases life and the electric motor is of the best quality.

-

Hot Selling for 100m3 Desander for Cleaning Drilling Mud

TR Solids control produce mud desander and drilling fluids desander.Drilling Mud Desander for Mud Circulating System. Drilling Mud Desander Consists of Desander Cyclone.

Drilling Fluids Desander for Mud Circulating System Mud Desander also called drilling fluids Desander, It is the third piece of equipment in the mud recycling system. Mud Desander is used after the drill fluid has already been treated under the mud shale shaker and mud degasser. Mud Desanders make separations between 40 and 100 microns and offer the flexibility of mounting either one, two, or three 10” desander cyclone over a cone underflow pan.

Mud Desander is a useful mud recycling equipment that removes the solid particles within a specific range, from the mud (or drill fluid). Mud Desanders make separations between 40 and 100 microns and offer the flexibility of mounting either one, two, or three 10” desander cyclone over a cone underflow pan. The underflow can be discarded or directed onto a vibrating screen for further processing. Drilling Fluids Desanders are also available in vertical or inclined manifold stand-alone models, or for inclined mounting on Drilling Shale Shakers.

-

Rapid Delivery for Factory Hot Sale Vertical Glass Washer and Dryer on Sale

Vertical Cutting Dryer uses centrifugal force to dry drilled solids.

Vertical Cuttings Dryer continues to be the industry choice as the most reliable and efficient solution when dealing with waste cuttings. The TR Vertical Cutting Dryer uses centrifugal force to dry drilled solids in oil or synthetic base fluids. Vertical cuttings dryer can recover up to 95% of drilling fluids. vertical dryer cuttings that can range between 6% and 1% oil by weight.

Vertical Cutting Dryer is a single level continuous working horizontal scraper discharging centrifuge. TR series It can effectively recover the oil components in the drilling chips, and can effectively meet the requirements of curing transportation and meet the requirements of environmental protection standards. A stainless steel screen bowl traps “wet” solids and accelerates them up 900RPM with G force to 420G. Vertical Cutting Dryer is very good. Liquid is forced through the screen bowl openings, while “dry” solids are extracted by the angled flights attached to the cone, which rotate slightly slower than the bowl. Tungsten carbide protects the flights from abrasive solids and ensures long operational life. This aids in maintaining a constant gap between the scroll and screen bowl, which is crucial for proper operation.

Vertical cuttings dryer can recover up to 95% of drilling fluids. vertical dryer cuttings that can range between 6% and 1% oil by weight.

-

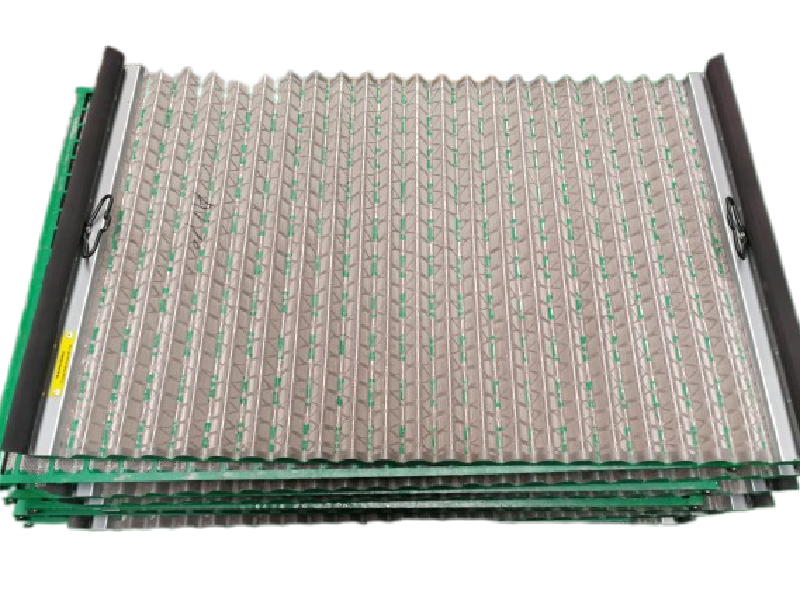

Factory supplied 4-Panel Shale Shaker Mud Cleaner Screen

Pyramid shaker screen also called three-dimensional shale shaker screen. TR is a FLC 500 PMD Shaker Screen manufacturer and China Pyramid shaker screen supplier .

FLC 500 PMD Shaker Screen is used to Derrick 503 Shale Shaker . Pyramid shaker screen is popular in Saudi Arabia.

FLC 500 PMD Shaker Screens are used as the substitute screen for:

• FLC (Flo-Line Cleaner) 503 shaker.

• FLC (Flo-Line Cleaner) 504 shaker.

• FLC (Flo-Line Cleaner) 503 drying shaker.

• FLC (Flo-Line Cleaner) 504 drying shaker.

• FLC (Flo-Line Cleaner) 513 shaker.

• FLC (Flo-Line Cleaner) 514 shaker.

• FLC (Flo-Line Cleaner) 513 VE (Vapor Extraction).

• FLC (Flo-Line Cleaner) 514 VE (Vapor Extraction). -

China Gold Supplier for API RP 13c Mi-Swaco Mongoose Steel Frame Shale Shaker Screens

Mongoose Screen is designed for the replacement screen of Mongoose Pro Shaker Screen. TR is a SWACO Screen manufacturer and China Mongoose Screen supplier .

Replacement Mongoose Screen have steel and PT frame types for your choice. Swaco mongoose pro shaker screen size is imperative in ensuring a job well done for mud flowing over the shale shakers.

Technical Parameter

• Mesh Material: stainless steel 304/316/316 L.

• Frame Material: Q235 steel/PT.

• Screen Type: XL, XR, HC, MG.

• API RP 13C Designation: API 20 – API 325.

• Package: packed in paper carton, shipped by wooden case. -

Manufacturing Companies for Beyond Solids Control System Oil Well Drilling Rigs Screen Shale Shaker Screen

Drilling Shale Shaker is the third generation of linear motion shaker.Drilling Shale Shaker is using the horizontal excitation of vibration motor as vibration source, material on the sieve was up forward for linear motion,referred to as Linear Shaker, also known as linear shaker; Drilling Shale Shaker is the most widely used mud shale Shaker. All Mud Shale Shaker is TR Solids Control designed by ourselves, including Balanced Elliptical motion Shaker and Mongoose shale shaker.All shaker screens can be fit on shakers by wedge blocks or hooks.We can according to customer’s demand, linear motion, or balanced elliptical motion and double-track movement.

-

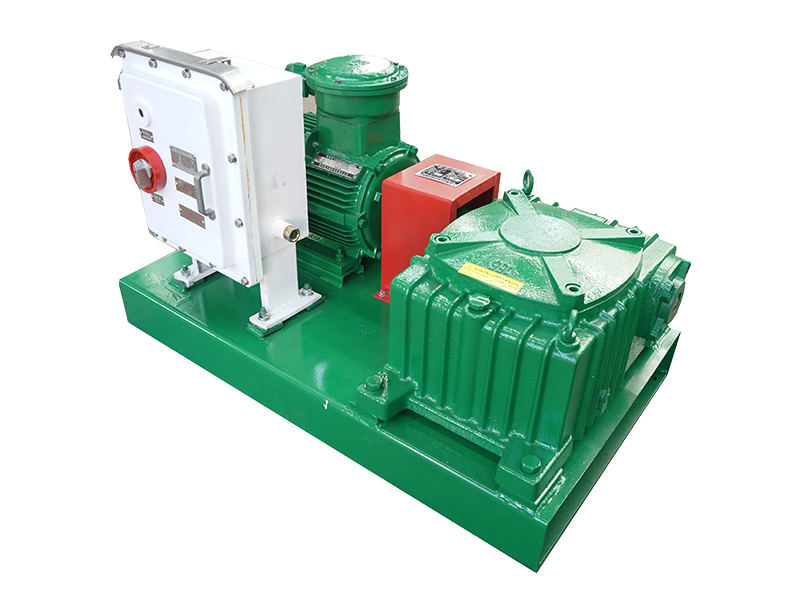

Professional Design Silica Sand Production Line Use Mixing Tank, Mini Mixing Agitator

Mud Agitator and Drilling fluids agitator are used for solids control system. TR Solids Control is an mud agitators manufacturer.

Mud Agitators are designed to mix and suspend the solids using axial flow, promoting low particle size degradation and effective polymer shear. Unlike mud guns, the mud agitator is relatively a low energy device, easy to operate and inexpensive to maintain. Our standard horizontal and vertical mud agitators range in 5 to 30 horsepower with an explosion proof motor and gear reducer. We size mud agitators according to the configuration and maximum mud weight. TR Solids Control is an Drilling fluids agitator manufacturer.

Drilling Mud Agitators are designed to mix and suspend the solids using axial flow, promoting low particle size degradation and effective polymer shear. Unlike mud guns, the mud agitator is relatively a low energy device, easy to operate and inexpensive to maintain. Our standard horizontal and vertical mud agitators range in 5 to 30 horsepower with an explosion proof motor and gear reducer. We size mud agitators according to the configuration and maximum mud weight.

-

2019 Latest Design Better Centrifugal Pump 8X6X14, 2.5″ Mud Hog TM, Mission Supreme Halco Design, Standard Frame, Grease Lube, Tungsten Carbide mechanical Seal HS864hisita0

Drilling Mud Centrifugal pump is often used for desander and desilter mud supply system. Mission Pump mainly supplies to solids control circulating system of oilfield drill rig.

Mud Centrifugal Pumps is designed and engineered to handle abrasive, viscous and corrosive fluids in drilling fluid or industrial slurry applications. Mission Pump performance is matched by exceptional performance, high volume, high temperature capabilities, long service life, ease to maintenance, overall economy and greater savings. Centrifugal Mud Pumps are currently in operation on land-based and offshore drilling rigs around the world. We will offer the best choice for the intended application, taking into consideration fluid conditions.

Mission Pump mainly supplies to solids control circulating system of oilfield drill rig,and be used to provide drilling liquid with a certain discharge capacity and pressure to sand, desilter and mud mixer,to assure these equipments work efficiently.Mud Centrifugal pump adopts advanced design theory for pumping drilling fluid or industrial suspension (slurry).Drilling mud centrifugal pump can pump abrasive, viscosity and corrosive liquid. We will provide customers with the best products to meet the needs of different conditions.

-

Factory made hot-sale Oil Drilling Rig Solid Control System Mud Oil Shale Screen Shaker

Hyperpool PMD Screen is designed for the replacement screen of Derrick Hyperpool Shakers. TR is a Derrick Hyperpool Screens manufacturer and China PMD HYP Screen supplier .

Hyperpool PMD Screen is also known as PMD HYP Screen

Technical Parameter

• Material: stainless steel 304/316/316 L.

• Construction Type: PMD (perforated wear plate).

• Wear Mesh Shape: rectangle.

• API RP 13C Designation: API 20 – API 325.

• Series: DX, DF, HP optional.

• Color: green.

• Package: 2 pcs per carton, 20 pcs/wooden case.