-

Discount wholesale Easy Operation Multiple Disc Sludge Drying Machine Dewatering Decanter Centrifuge

TR Solids Control is an Dewatering centrifuge Supplier. The sludge dewatering centrifuge produced by TR Solids Control has been widely praised by customers.

A sludge dewatering centrifuge uses a fast rotation of a “cylindrical bowl” to separate wastewater liquid from solids. The wastewater centrifuge dewatering process removes more water than other methods and leaves solid material that is known as cake. Dewatering means less tank space is needed to store waste products.

-

China Wholesale Clarification Tubular Bowl Fruit Centrifuge

TR Solids Control is an Dewatering centrifuge Supplier. The sludge dewatering centrifuge produced by TR Solids Control has been widely praised by customers.

A sludge dewatering centrifuge uses a fast rotation of a “cylindrical bowl” to separate wastewater liquid from solids. The wastewater centrifuge dewatering process removes more water than other methods and leaves solid material that is known as cake. Dewatering means less tank space is needed to store waste products.

-

Renewable Design for Algae Harvest Tubular Separator Centrifuge

TR Solids Control is an Dewatering centrifuge Supplier. The sludge dewatering centrifuge produced by TR Solids Control has been widely praised by customers.

A sludge dewatering centrifuge uses a fast rotation of a “cylindrical bowl” to separate wastewater liquid from solids. The wastewater centrifuge dewatering process removes more water than other methods and leaves solid material that is known as cake. Dewatering means less tank space is needed to store waste products.

-

Factory Directly supply Duplex Stainless Steel and High G- Force and High Capacity Decanter Centrifuge

TR Solids Control is an Dewatering centrifuge Supplier. The sludge dewatering centrifuge produced by TR Solids Control has been widely praised by customers.

A sludge dewatering centrifuge uses a fast rotation of a “cylindrical bowl” to separate wastewater liquid from solids. The wastewater centrifuge dewatering process removes more water than other methods and leaves solid material that is known as cake. Dewatering means less tank space is needed to store waste products.

-

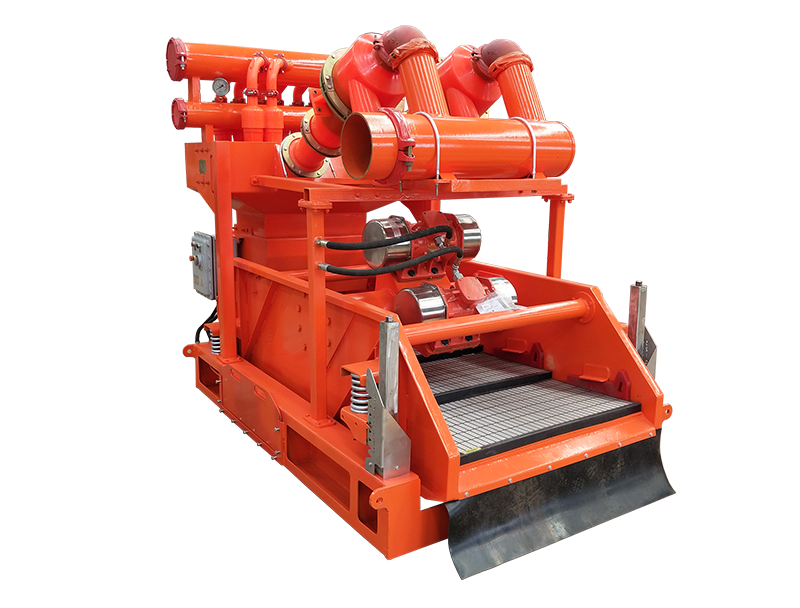

Reasonable price for Solid Control Equipment Mud Cleaner/Mud Desilters for drilling mud

Mud Cleaner equipment is a combination of desander, desilter hydro cyclone with an underflow shale shaker. TR Solids Control is Mud Cleaner manufacture.

Mud cleaner is a versatile device that is used to separate big solid components and other slurry materials from drilled mud. In this article, we’re going to talk about the Mud Cleaner from TR Solids Control.

Mud Cleaner equipment is a combination of desander, desilter hydro cyclone with an underflow shale shaker. To overcome limitations that are present in many solid removal equipment, ‘new’ equipment was developed with the purpose of removing drilled solids from weighted muds. The Mud Cleaner does remove most of the drilled solids while also retaining the barite as well as the liquid phase present in the mud. The discarded solids are sieved to discard larger solids, and returned solids are smaller even from the screen size of the liquid phase.

Mud Cleaner is the second class and the third class solids control equipment which is the newest type to treat the drilling fluid. At the same time drilling Mud cleaner has the higher cleaning function compared with separated desander and desilter. In addition to the reasonable design process, it equals another shale shaker. Fluids mud cleaner structure is compact, it occupys small space and the function is powerful.

-

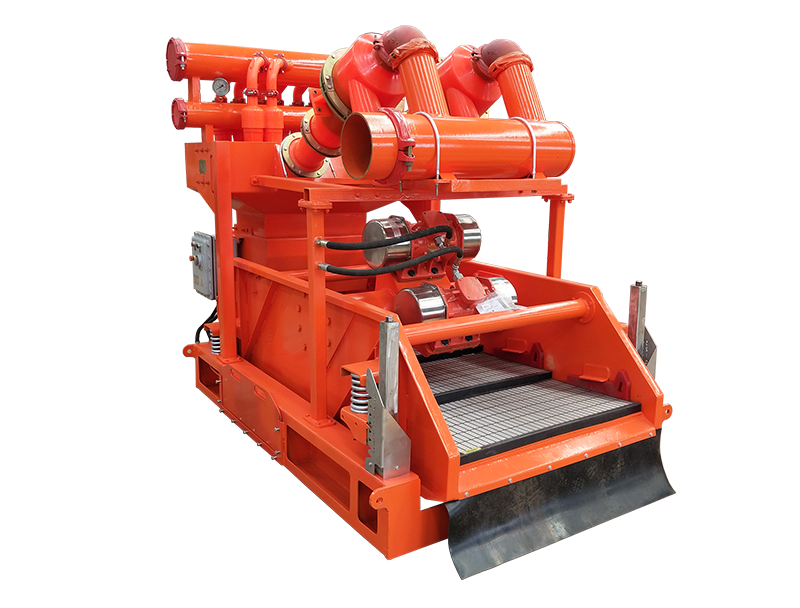

Factory supplied High Quality Oil Drilling Rig Equipment Mud Cleaner Desilter for Mud Clean

Mud Cleaner equipment is a combination of desander, desilter hydro cyclone with an underflow shale shaker. TR Solids Control is Mud Cleaner manufacture.

Mud cleaner is a versatile device that is used to separate big solid components and other slurry materials from drilled mud. In this article, we’re going to talk about the Mud Cleaner from TR Solids Control.

Mud Cleaner equipment is a combination of desander, desilter hydro cyclone with an underflow shale shaker. To overcome limitations that are present in many solid removal equipment, ‘new’ equipment was developed with the purpose of removing drilled solids from weighted muds. The Mud Cleaner does remove most of the drilled solids while also retaining the barite as well as the liquid phase present in the mud. The discarded solids are sieved to discard larger solids, and returned solids are smaller even from the screen size of the liquid phase.

Mud Cleaner is the second class and the third class solids control equipment which is the newest type to treat the drilling fluid. At the same time drilling Mud cleaner has the higher cleaning function compared with separated desander and desilter. In addition to the reasonable design process, it equals another shale shaker. Fluids mud cleaner structure is compact, it occupys small space and the function is powerful.

-

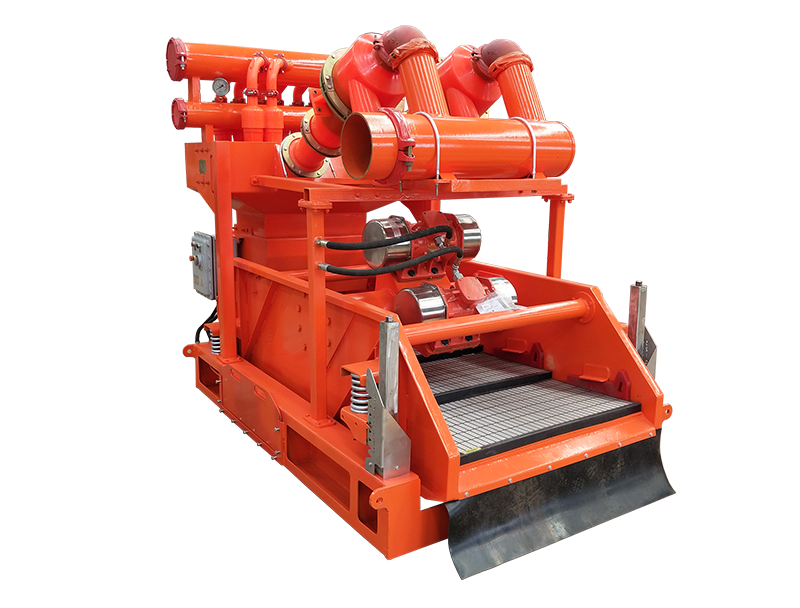

OEM/ODM China Mud Cleaner/Mud Desilters for Drilling Mud Solid Control Equipment

Mud Cleaner equipment is a combination of desander, desilter hydro cyclone with an underflow shale shaker. TR Solids Control is Mud Cleaner manufacture.

Mud cleaner is a versatile device that is used to separate big solid components and other slurry materials from drilled mud. In this article, we’re going to talk about the Mud Cleaner from TR Solids Control.

Mud Cleaner equipment is a combination of desander, desilter hydro cyclone with an underflow shale shaker. To overcome limitations that are present in many solid removal equipment, ‘new’ equipment was developed with the purpose of removing drilled solids from weighted muds. The Mud Cleaner does remove most of the drilled solids while also retaining the barite as well as the liquid phase present in the mud. The discarded solids are sieved to discard larger solids, and returned solids are smaller even from the screen size of the liquid phase.

Mud Cleaner is the second class and the third class solids control equipment which is the newest type to treat the drilling fluid. At the same time drilling Mud cleaner has the higher cleaning function compared with separated desander and desilter. In addition to the reasonable design process, it equals another shale shaker. Fluids mud cleaner structure is compact, it occupys small space and the function is powerful.

-

Low MOQ for High Quality Drilling Fluid Oil Filed Drilling Mud Cleaner for Solids Control

Mud Vacuum Degasser and Drilling Vacuum Degasser are special purpose product for gas treatment in drilling fluids.

Mud Vacuum Degasser is the most common form of degassing systems used in the oil & gas industry. Drillng fluid is pulled into the tank by vacuum action. The fluid rises inside the tank and is distributed over a series of plates which releases the gas bubbles from the drilling fluid.

Mud Vacuum Degasser is a special purpose product for gas treatment in drilling fluids. This unit is positioned downstream from shale shaker, mud cleaner and mud gas separator, while hydrocyclones and centrifuges follow in the arrangement. It is used to remove small entrained gas bubbles left in the mud by mud gas separator.

Mud Vacuum Degasser is also called mud/Gas separator. Mud/gas separators (Degasser) is the first units of solids control equipment arranged to treat drilling mud. As such, they process all of the drilling mud from the flow line before the mud reaches the primary shale shakers.

-

OEM Factory for Shale Shaker Shale Shaker Screen for Mud Circulating Clean

Drilling Shale Shaker is the third generation of linear motion shaker.Drilling Shale Shaker is using the horizontal excitation of vibration motor as vibration source, material on the sieve was up forward for linear motion,referred to as Linear Shaker, also known as linear shaker; Drilling Shale Shaker is the most widely used mud shale Shaker. All Mud Shale Shaker is TR Solids Control designed by ourselves, including Balanced Elliptical motion Shaker and Mongoose shale shaker.All shaker screens can be fit on shakers by wedge blocks or hooks.We can according to customer’s demand, linear motion, or balanced elliptical motion and double-track movement.

-

Top Grade Drilling Rig Fluid Solid Control Mud Shale Flc 500 Wave Type Shale Shaker Screen Oil Vibrating Sieving Screen Energy & Mining

Drilling Shale Shaker is the third generation of linear motion shaker.Drilling Shale Shaker is using the horizontal excitation of vibration motor as vibration source, material on the sieve was up forward for linear motion,referred to as Linear Shaker, also known as linear shaker; Drilling Shale Shaker is the most widely used mud shale Shaker. All Mud Shale Shaker is TR Solids Control designed by ourselves, including Balanced Elliptical motion Shaker and Mongoose shale shaker.All shaker screens can be fit on shakers by wedge blocks or hooks.We can according to customer’s demand, linear motion, or balanced elliptical motion and double-track movement.

-

High reputation Decanter Centrifuge for Oil Drilling Mud Separation

TR solids control is the production Drilling Mud Decanter Centrifuge and waster decanter centrifuge manufacturer.

Drilling Mud decanter Centrifuge is widely used in oil and gas drilling, Waste Decanter Centrifuge used in vertical cuttings dryer, remove all the solids in the drilling fluids.

Drilling Mud decanter centrifuge adopts centrifugal force to separate solid particles out of drilling fluid. Different solid or particle have different density and flow speed, drilling mud decanter centrifuges also can separate particles as different size and density. Mud Centrifuges is widely used in oil and gas drilling, chemical, foodstuff, pharmacy, mineral beneficiation, water treatment, etc. industries.Waste Decanter Centrifuge used in drilling waste management(DWM).

-

2019 wholesale price Solid Control Equipment Desander Desilter for Oil and Gas Drilling Rig Oil Well Mud Cleaning

Drilling waste management is used for taking drilling fluids from the drilling cuttings and clean the fluids for resuse.

Drilling waste management system are drying shaker, vertical cutting dryer, decanter centrifuge, screw conveyor, screw pump and mud tanks. The drilling waste management can effectively control the moisture content (6%-15%) and oil content (2%-8%) in drilling cuttings and stabilizes the liquid phase performance.

Drilling waste management system, also called as drill cutting treatment system or drilling cutting management system. According to different applications, it can be classified as water-based drilling waste management system and oil-based drilling waste management system. The main system equipments are drying shaker, vertical cutting dryer, decanter centrifuge, screw conveyor, screw pump and mud tanks. The drilling waste management system can effectively control the moisture content (6%-15%) and oil content (2%-8%) in drilling cuttings and stabilizes the liquid phase performance.

TR drilling waste management is used for taking drilling fluids from the drilling cuttings and clean the fluids for resuse. It is to maximize the recycling of drilling fluids, and minimize the drilling waste in order to save cost for operators.