Products

Factory Free sample Lwf Horizontal Decanter Centrifuge for Drilling Waste

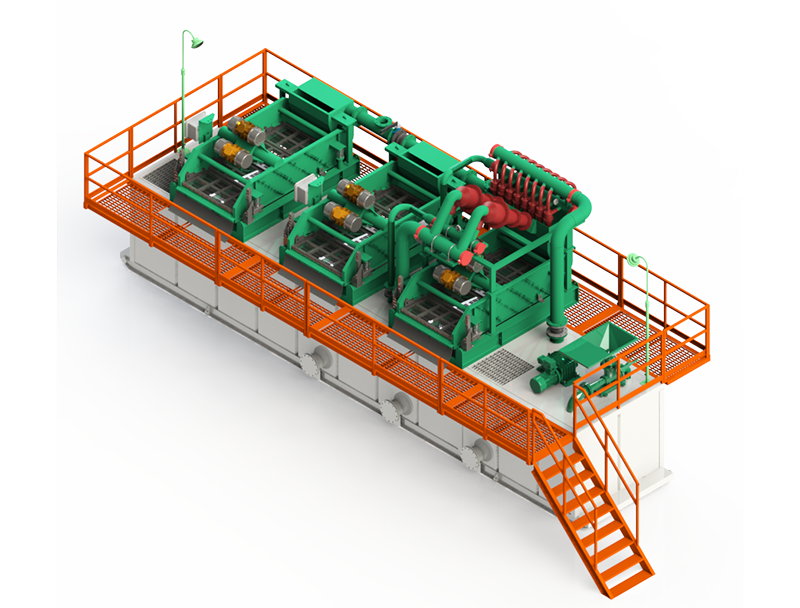

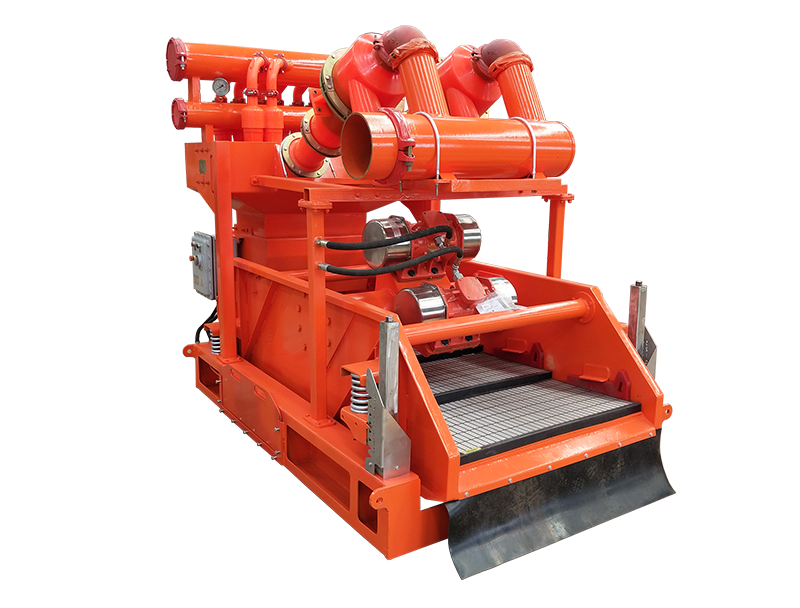

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for Factory Free sample Lwf Horizontal Decanter Centrifuge for Drilling Waste, For those who pursuit the Hi-quality, Hi-stable, Aggressive price components, organization name is your greatest choice!

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for China Centrifuge and Decenter Centrigue, Strong infrastructure is the have to have of any organization. We’re backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our solutions worldwide. To maintain smooth work flow, we’ve got sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we’ve been able to accomplish voluminous production without compromising on the quality.

Features

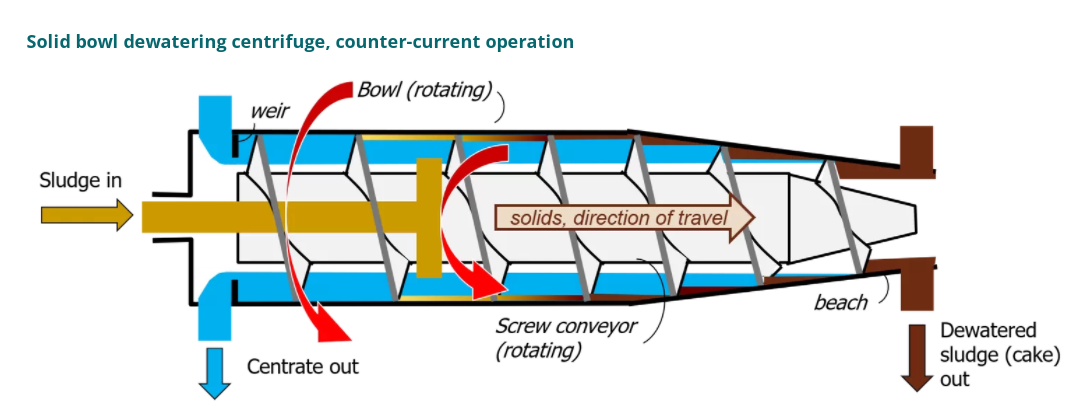

Dewatering Centrifugation is used for both thickening and dewatering of sewage sludge, where dewatered sludge has a higher dry solids (DS) concentration. The centrifuge technologies used for each is almost identical. The key operational differences between the two functions are:

-

the rotation speed employed

-

the throughput, and

-

the nature of the concentrated solids product generated.

Dewatering demands more energy than thickening since more water must be removed to achieve the higher solids concentrations. The dewatered product, whose dry solids (DS) content may be as high as 50%, takes the form of a cake: a deformable semi-solid which forms lumps rather than a free-flowing fluid. It can therefore only be conveyed using a conveyor belt, whereas a thickened product retains the fluid properties of the feed and can be pumped.

As with thickening, the most common type of centrifuge used for dewatering applications is the solid bowl centrifuge, usually referred to as a decanter or a decanting centrifuge. Its dewatering performance and solids recovery depends on the feed sludge quality and dosing conditions

Technical Parameters

|

Model |

TRGLW355N-1V |

TRGLW450N-2V |

TRGLW450N-3V |

TRGLW550N-1V |

|

Bowl Diameter |

355mm (14inch) |

450mm (17.7inch) |

450mm (17.7inch) |

550mm (22inch) |

|

Bowl Length |

1250mm(49.2inch) |

1250mm(49.2inch) |

1600(64inch) |

1800mm(49.2inch) |

|

Max Capacity |

40m3/h |

60m3/h |

70m3/h |

90m3/h |

|

Max Speed |

3800r/min |

3200r/min |

3200r/min |

3000r/min |

|

Rotary Speed |

0~3200r/min |

0~3000r/min |

0~2800r/min |

0~2600r/min |

|

G-Force |

3018 |

2578 |

2578 |

2711 |

|

Separation |

2~5μm |

2~5μm |

2~5μm |

2~5μm |

|

Main Drive |

30kW-4p |

30kW-4p |

45kW-4p |

55kW-4p |

|

Back Drive |

7.5kW-4p |

7.5kW-4p |

15kW-4p |

22kW-4p |

|

Weight |

2950kg |

3200kg |

4500kg |

5800kg |

|

Dimension |

2850X1860X1250 |

2600X1860X1250 |

2950X1860X1250 |

3250X1960X1350 |

We are committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for Factory Free sample Lwf Horizontal Decanter Centrifuge for Drilling Waste, For those who pursuit the Hi-quality, Hi-stable, Aggressive price components, organization name is your greatest choice!

Factory Free sample China Centrifuge and Decenter Centrigue, Strong infrastructure is the have to have of any organization. We’re backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our solutions worldwide. To maintain smooth work flow, we’ve got sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we’ve been able to accomplish voluminous production without compromising on the quality.